Support CleanTechnica’s work through a Substack subscription or on Stripe.

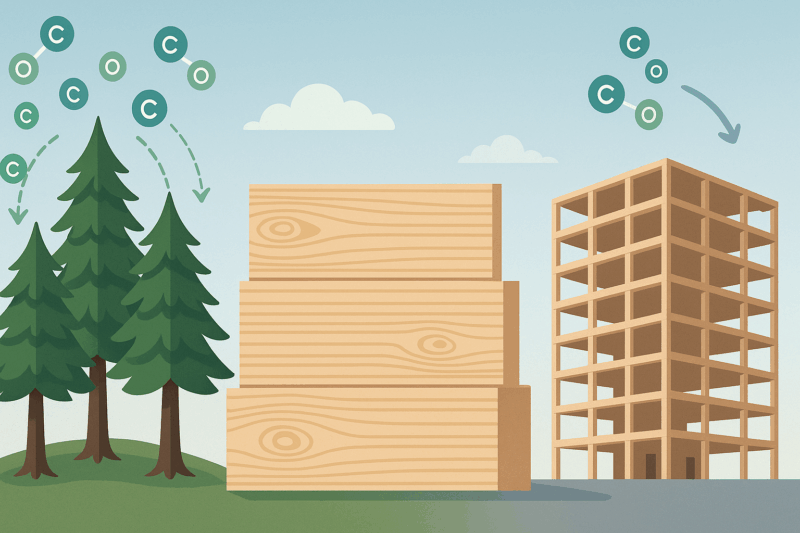

Carbon accounting is one of the most important but least understood aspects of the discussion about cross laminated timber. The claim that CLT is carbon negative depends on how one defines system boundaries and how accounting rules are applied. Trees absorb carbon as they grow, storing it in their fibers. When those trees are harvested and converted into structural panels, that carbon remains locked in place for as long as the building stands.

The series so far has built a clear case for mass timber as Canada’s fastest lever to address housing, economy, and climate together. The opening article argued that CLT and modular construction can double housing supply while cutting embodied carbon. The second examined Mark Carney’s Build Canada Homes initiative and showed how government can act as an anchor buyer to turn policy into real housing output. The third mapped out Canada’s mass-timber playbook, stressing the need for an integrated value chain from sawmills to modules. The fourth explored how CLT substitution bends long-term cement and steel demand curves, making heavy industry decarbonization more achievable.

Emissions are released at every step of the process, from harvesting and transport to drying, adhesives, and assembly. The balance between stored carbon and emitted carbon is what matters, and the balance is striking. Environmental product declarations, or EPDs, for CLT produced in Canada already show that more carbon is stored than emitted, cradle to gate. That makes the product net negative before it even reaches a construction site.

The Element5 EPD is a case in point. Process emissions associated with producing a cubic meter of CLT are on the order of 120 kilograms of CO2. That includes energy for harvesting and transport, kiln drying, adhesive production, and assembly. By contrast, that same cubic meter of CLT stores close to a ton of CO2 absorbed during tree growth. The balance is negative by a wide margin. Yet many standards require that the stored carbon be reported separately, not netted out against emissions. The logic is that the storage is temporary until the end of life fate of the material is known. If the wood is incinerated, that carbon is released. If it is landfilled, some of it is emitted as methane without capture. If it is reused in another building or sequestered in products like biochar, it can remain locked away for even longer. The official accounting treats storage as conditional, but the practical climate benefit is clear when timber is used in long lived structures.

The diagnosis is straightforward. Biogenic carbon is real, but accounting frameworks are conservative about crediting it. This caution leads to under-recognition of the climate benefit of mass timber in current programs. Policies and standards could change that. Canada should require EPDs for all structural materials so that embodied carbon is transparently measured and compared. Programs should reward long term storage in buildings by granting credit for timber that is expected to remain in place for fifty to a hundred years. Alignment with ISO and EN standards would ensure credibility while Canadian policy could lead by integrating recognition of storage into building performance targets. Some European programs already do this by counting the storage benefit of wood when evaluating low carbon buildings.

Making CLT carbon negative in practice depends on more than accounting. It depends on choices across the lifecycle. Designing buildings for longer life ensures that carbon remains stored for many decades. Designing for reuse allows panels and beams to be disassembled and placed into new structures rather than downcycled or burned.

End of life management is critical. If panels are incinerated without carbon capture, stored carbon is lost. If they are landfilled without gas management, some portion escapes as methane. Better outcomes come from reuse, recycling, or conversion into stable forms like biochar. Landfills with methane capture can also mitigate emissions. Canada can set standards that drive builders and municipalities toward these outcomes. A national approach to EPDs for timber that includes these pathways would help codify the carbon benefit.

Complementary decarbonization of the supply chain strengthens the case further. Diesel equipment in forests, fossil fuel-powered kilns, and petrochemical adhesives all add to the positive side of the emissions ledger. Electrifying harvesting and hauling, switching kilns to biomass or heat pump systems, and moving bio-based adhesives from pilot to production all reduce process emissions. The result is a lower positive figure in the EPD and a stronger negative balance when paired with stored carbon. Canada’s electricity grid is already relatively clean and will be net zero by 2035 under federal targets. That means that electrification translates directly into reductions. The opportunity is to drive that positive number down toward zero, making the negative storage value stand out even more.

Charts that show the breakdown help clarify the story. A typical EPD presents positive emissions in one column and biogenic storage in another. The difference is what matters. Waterfall diagrams of emissions from harvesting to end of life show where reductions can be made and how storage dominates the balance. Policy charts can map different credit pathways, showing what is recognized under current standards and what could be recognized if programs evolve. Together these visual tools make the case that CLT is not only net negative in practice, but should be counted that way in official frameworks.

Risks remain. Global accounting standards are not consistent. Some countries require EPDs, others do not. Some credit storage, others treat it separately. Without harmonization, comparisons across products and geographies are difficult. Skepticism about permanence will continue, especially from industries that compete with timber. Adoption of EPD requirements can be slow, and some builders may resist additional reporting burdens.

But the enablers are also present. There is growing demand from developers and investors for transparent embodied carbon data. European precedents show that storage can be credited responsibly. Canada’s clean electricity and sustainable forestry base make it well suited to lead in demonstrating a carbon negative timber industry.

The conclusion is that CLT already stores more carbon than it emits, cradle to gate. With electrified supply chains and sustainable forestry practices, its net climate benefit is undeniable. Accounting systems need to evolve to reflect this reality and to reward long term carbon storage in buildings. When they do, CLT will not only be recognized as carbon negative but will also be incentivized in policy and procurement. Canada has an opportunity to lead in marrying sustainable forestry, industrial electrification, and transparent carbon accounting. The result would be a building material that is strongly carbon negative in fact and in law, aligning the needs of housing, economy, and climate.

Sign up for CleanTechnica’s Weekly Substack for Zach and Scott’s in-depth analyses and high level summaries, sign up for our daily newsletter, and follow us on Google News!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one on top stories of the week if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy