Support CleanTechnica’s work through a Substack subscription or on Stripe.

Canada has been facing a housing affordability crisis for years, and it has only become more acute. Population growth, immigration, and urban concentration have run headlong into a construction industry that has not kept pace. Annual completions of 240,000 to 270,000 units fall well short of the 500,000 required to keep housing affordable. That gap shows up in rising rents, worsening homelessness, and ownership slipping out of reach for younger Canadians. It also shows up in the economy, as too much household income is locked up in shelter, and in climate policy, because building slowly and with high carbon materials locks in emissions for decades.

The formally announced Build Canada Homes initiative is an attempt to confront all of that at once. With $13 billion in initial capitalization and a mandate to double construction rates, it is not just another housing program. It is a federal development agency designed to build directly, partner with private developers, and deploy modern methods of construction at scale. The government has identified 88 federal properties that will be made available, transferred Canada Lands Company into the new agency, and signaled that public land and public money will be leveraged to move projects forward faster. The three pillars are clear: direct partnerships and direct builds, mainstreaming factory built and mass timber housing, and ensuring Canadian supply chains benefit.

A central feature of Build Canada Homes is its focus on affordable and social housing rather than relying solely on market supply. The agency is mandated to build and preserve units that remain permanently affordable, including supportive housing for people experiencing homelessness, rentals for low and moderate income households, and mixed income communities that reduce stigma by serving a broad spectrum of Canadians. This emphasis has important implications. By expanding the non-market stock, the program builds a foundation of housing insulated from speculative pressures, stabilizing communities over the long term. Inclusion of mixed income developments, as seen in successful models in Vienna, ensures political support and better integration into cities. It also shifts the federal role from merely enabling private developers to directly shaping housing outcomes, embedding affordability as a permanent feature of the housing landscape.

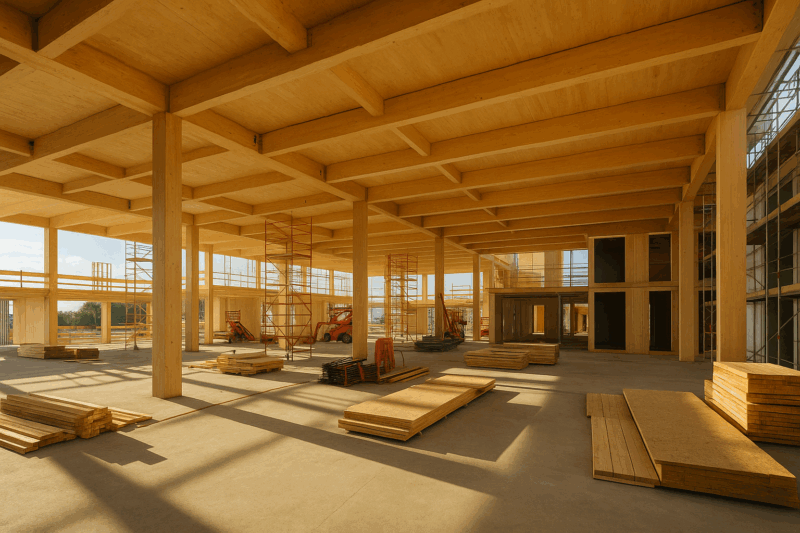

Traditional construction will not get Canada to 500,000 units per year. It is too slow, too labour intensive, and too vulnerable to weather and permitting delays. Prefabricated modular housing and mass timber construction are the levers that can shift the pace, as I laid out in my recent series on mass timber, collated into a report. Factories can work year round, producing modules and CLT panels with precision, while sites are being prepared in parallel. Once ready, structures can be assembled in weeks instead of months. The potential speed gains are 30% to 50%, and the carbon reductions from replacing concrete and steel range from 15% to 40%. I have argued for some time that this is one of the fastest ways to deal with the housing gap while also making progress on jobs and climate.

Canada’s industrial opportunity is significant. Our forests can supply the raw material, but mills, kilns, adhesives, and production lines need to be retooled and expanded. To meet even part of the Build Canada Homes target, the country will need a dozen or more large modular or CLT factories by 2030. That scale of manufacturing requires confidence that there will be demand year in and year out. Without it, factories falter, as Structurlam’s experience in British Columbia and Arkansas demonstrated when a single lost order threatened its survival. Build Canada Homes can serve as the anchor customer, offering offtake contracts, loans, and equity that make factories viable. The $25 billion in low cost loans and $1 billion in equity earmarked for manufacturing are exactly the kind of tools required to create a stable industry.

There are bottlenecks. Sawmills are optimized for small dimensional lumber, not for mass timber lamella. Drying is energy intensive and often fossil fuel powered. Adhesives are almost entirely petrochemical, with bio based alternatives not yet commercial at scale. Insurance premiums for tall wood buildings remain higher than for concrete or steel, and provincial code adoption is inconsistent. Labour shortages in both traditional trades and in the new skills required for factory production could constrain growth. These are not theoretical risks. They are the practical barriers that must be addressed if Canada is to industrialize construction. That means electrifying kilns, advancing adhesives research, pooling insurance data, pre-approving designs, and training a new workforce.

The payoff is meaningful. Doubling construction will not reduce prices overnight, but it will slow the climb and start to close the affordability gap. More rental units will raise vacancy rates and take some of the pressure out of rent increases. Affordable ownership units combined with GST relief will give first time buyers an entry point. In Toronto and Vancouver, where supply has been most constrained, the impact will be strongest. In northern and Indigenous communities, modular approaches can quickly reduce overcrowding and improve health outcomes. Nationally, building 500,000 units per year by 2030 is the line of sight to restoring affordability to 2019 levels, according to CMHC analysis.

Funding adequacy is always in question. $13 billion only covers a fraction of total costs, roughly $20,000 per unit if spread across the target, against per unit costs that are an order of magnitude higher. But this is seed capital, intended to leverage private and provincial funds, recycle repayments, and reduce risk so that other money flows. Vienna’s cost rent model shows how revolving loans, public land, and limited profit developers can sustain affordability at scale. Build Canada Homes can adapt that logic. A revolving fund structure, multi year commitments, and offtake contracts are how to stretch dollars and sustain the program.

Global examples underline both the potential and the risks. Singapore’s Housing and Development Board showed what state led development can achieve when land, planning, and construction are centralized, though it has had to manage rising resale prices. Vienna’s broad based social housing demonstrates the power of serving middle class and low income households together, keeping housing non-stigmatized and politically resilient. Sweden’s Million Homes program showed how industrialized methods can deliver volume but also how supply must keep up to avoid shortages and queues. Germany’s strong tenant protections underscore the importance of permanence in affordability. Build Canada Homes borrows from each model, but must be adapted to federalism and Canadian geography.

The climate benefits of this approach should not be discounted. Every cubic meter of CLT locks away about a ton of CO2 while emitting only around 120 kilograms in production. With electrified kilns, bio based adhesives, and sustainable forestry, mass timber can be net negative. Substituting timber for concrete and steel changes the demand curve for those industries, making their decarbonization paths more achievable. End of life strategies, from reuse and recycling to biochar, can extend storage further. Housing policy is rarely climate policy, but here they intersect directly.

Build Canada Homes is ambitious. It will face resistance, delays, and cost overruns if not managed well. But the alternative is continuing down a path of worsening affordability, higher emissions, and industrial stagnation. This is one of the clearest examples of a systemic solution that addresses multiple crises at once. Housing Canadians affordably, creating a new construction industry, and reducing carbon emissions are not separate goals. They are intertwined. If Canada follows through with urgency and consistency, the outcome could be a transformed housing landscape and a new industrial sector with global reach. That is the opportunity on the table.

Sign up for CleanTechnica’s Weekly Substack for Zach and Scott’s in-depth analyses and high level summaries, sign up for our daily newsletter, and follow us on Google News!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one on top stories of the week if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy